Hand cut stainless steel

My client picked this stainless steel bin up for the bar in his new restaurant. He wanted to turn it into three beer coolers so it was time to get to cutting.

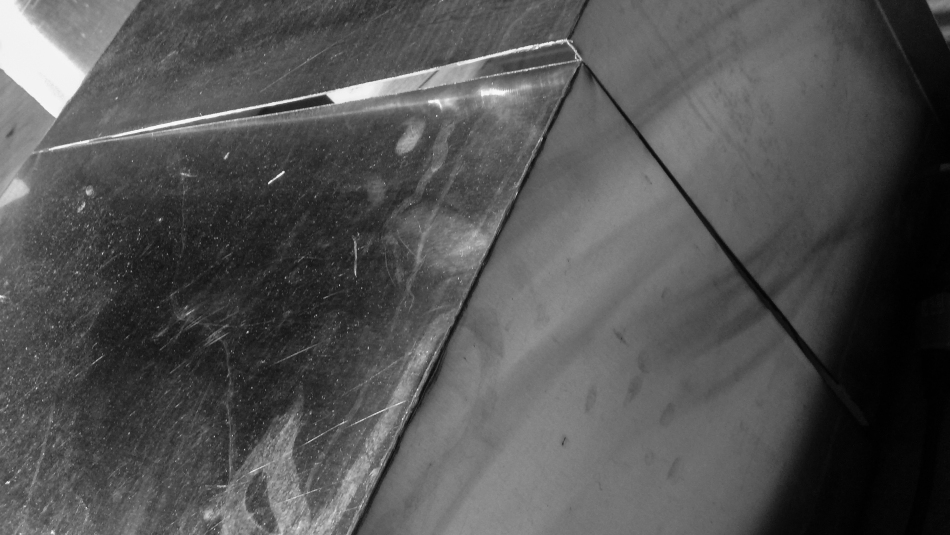

Heres the first shot as it showed up.

Here’s the second of four cuts required to complete this job. This is where fabricators start to get nervous because you might just might cut something without having to do any finishing work besides a quick buff to take off the razor sharp edges.

Here’s a shot after the top piece was cut off. All sides kiss the ground and it’s as level as it gets. Even my client which is reserved with his compliments noted on the accuracy of the cuts.

All these cuts were done by hand with a disc cutting wheel. All cuts ended up less than 1/32″ deviation from the cut line.

Cutting long lines like this with a cutting disc is really difficult and takes allot of time and patience to learn good technique and form.

Really excited for the next few weeks. Lots of new stuff will be going up. Thanks for reading.

share your thoughts,,